Why RFID is widely used by retailers under the covid-19 pandemic

Published on Monday, Jun 14, 2021

Due to the high labor costs in Europe, high freight costs and long delivery times have always been a major weakness affecting European e-commerce buyers, the major e-commerce companies have tried all kinds of solutions to hope to break through. It is under such circumstances that the Click-and-Collect delivery has appeared in the European retail market.

The definition of Click-and-Collect is “A shopping facility whereby a customer can buy or order goods from a store’s website and collect them from a local branch.” to sum it up is " buy online, pickup in store “, it can improve the quality and efficiency of order delivery

With the pandemic, consumers no longer go shopping outside, the shift in how people shop has impacted how retailers organize their inventory. But securing that revenue will require comprehensive inventory management that matches new consumer demands. Using RFID and providing clear visibility into stock numbers can help merchants deliver an efficient, profitable offering.

Radio Frequency Identification (RFID) is one of the most promising technologies to come to warehouses. As these facilities have become more crucial to the economy and more competitive, taking advantage of new technologies is essential. Radio frequency identification technology is a method that uses radio frequency signals to achieve spatial coupling (alternating magnetic field or electromagnetic field). The technology of contactless information transmission and achieving the purpose of identification through the transmitted information. Compared with automatic identification technologies such as barcodes, magnetic strips, magnetic cards, fingerprints, and optical characters, RFID has wireless read/write capabilities, strong signal penetration, long recognition distance, long service life, good environmental adaptability, and multiple tags at the same time. Recognition, large information storage capacity and data can be rewritten and other advantages,it can improve operations and efficiency throughout the warehouse.

Demand analysis

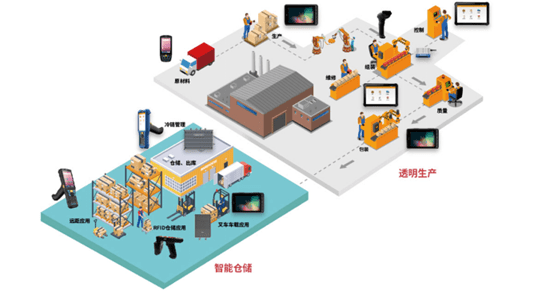

At present, the warehouse management systems that are widely used at home and abroad use barcodes or RFID. Compared with barcode recognition systems, RFID technology has many advantages. Therefore, the most researched is the application of RFID in storage.

The application of RFID technology can improve the current situation of insufficient warehouse management.

According to the analysis of the actual warehouse management process, the RFID storage management system should meet the following requirements:

- Realize the basic functions of management system applications, such as user authority management, data query, statistical management, etc.

- The use of RFID technology can automatically collect inventory information, improve the accuracy of goods inquiries and inventory quality, and accelerate the speed of goods in and out of the warehouse, to help enterprises reduce the cost of inventory management.

- It can provide administrators and users with timely and accurate inventory information. For example, the system can provide warnings when the inventory of the goods is lower than the safety inventory or the goods are expired.

How to perform warehouse management for RFID readers

1. Warehouse management

After receiving the warehousing order, put the product into the warehouse according to certain rules. When the RFID electronic tag (ultra high frequency) enters the electromagnetic wave range of the RFID fixed reader, it will be actively activated, and then the RFID electronic label and RFID fixed reading The writer communicates, and the relevant data can be collected into the system. You can also directly use the handheld terminal to collect data on the goods at close range. Then compare the relevant data with the order to check whether the quantity and model of the goods are correct. If there are errors or omissions, perform manual processing, and finally transport the goods to the designated location and place them in accordance with the rules.

2. Outbound management

Use RFID radio frequency reader to collect information of RFID electronic tags, check whether it corresponds to the plan, according to the picking plan, the outbound goods are sorted and processed. When there is an error, an alarm will be issued, and the staff can handle it on the spot. Finally Send the data to the management center to update the database to complete the delivery.

3. Inventory management

In accordance with the requirements of warehouse management, conduct regular and irregular inventory. Traditional inventory is time-consuming, labor-intensive, and error-prone. And all these RFID solve these problems. When there is an inventory plan, use RFID radio frequency reader to scan the goods, and the information of the clothing can be transmitted to the back-end database through the wireless network, and the information in the database Comparing, the generated difference information is displayed on the RFID handheld terminal in real time, and it is provided to the inventory staff for verification. After the inventory is completed, the inventory information is checked with the database information in the background, inventory completed.